Sustainable Technology

MrFeed® represents one of the most sustainable aquaculture and livestock feed products that can be produced at scale and at commercially viable costs

- Menon’s MrFeed® products have been developed through intensive research, development, validation and significant investment

- MrFeed® is produced through a proprietary, scalable hydrocarbon conversion process called Celtherm™ that is well ahead of competitive developments of ingredients

- The process utilizes unique starter materials to convert hydrocarbons into proteins, fats, enzymes and a spectrum of prebiotics

- All aspects of the technology, production process and formulations are patent protected

- Menon’s products have been validated externally through U.S. Government and state-sponsored studies

- Since the initial validations, the Company has evolved its production process to position MrFeed® as a standalone ingredient product

- Commercial testing in India, Malaysia, China and Vietnam has confirmed superiority in FCR (feed conversion rate), survivability, growth and disease remediation versus traditional fishmeal based diets

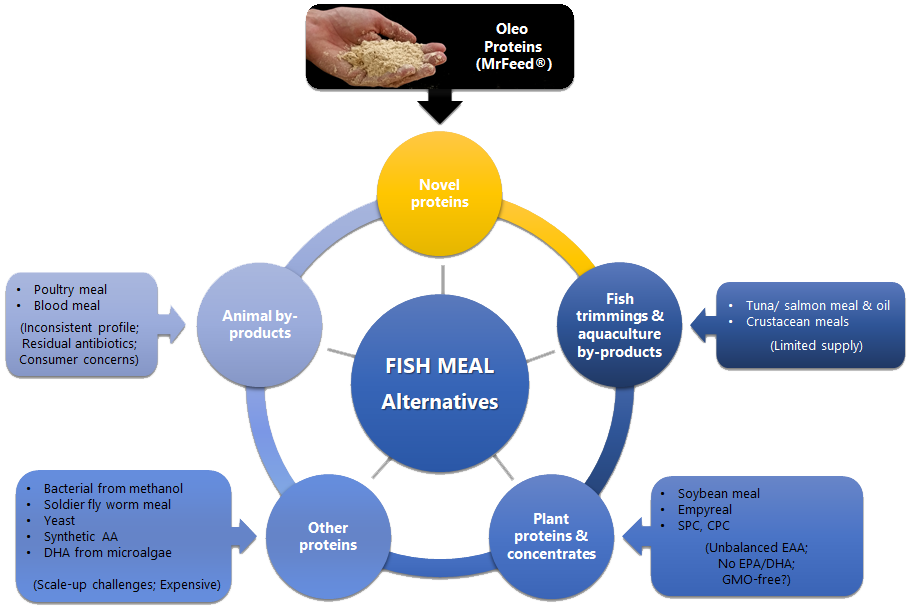

- Competing technologies utilize grains, insect meal, algae, single cell proteins, animal rendering byproducts, fish oils from sardines and cod, mixing anchovies, etc. to make feed. These products are not sustainable, scalable nor competitive and they propagate inefficiencies in digestibility and create anti-nutritional factors

- Menon proprietary technologies and processes utilize agricultural products and by-products and have economic and technical advantages over, including reducing the risk of supply shortages that are being experienced with other feed ingredient sources.

- No other feed can claim to be naturally and organically produced. MrFeed® is an organic, contaminant-free aquaculture and livestock feed ingredient

Sustainable Agricultural Inputs

The technology can utilize organic by-products and waste that currently go to landfills, significantly reducing the carbon footprint of aqua and livestock feed

Reduces Reliance on Fish Meal

- MrFeed® is produced using a proprietary fermentation process with the finished feed product possessing an amino acid profile that closely resembles fish meal

- The ability to replace fish meal reduces the pressure on the wild fish stocks that are currently being depleted as global demand for fish meal-based aquaculture and livestock feeds increase

Celtherm™

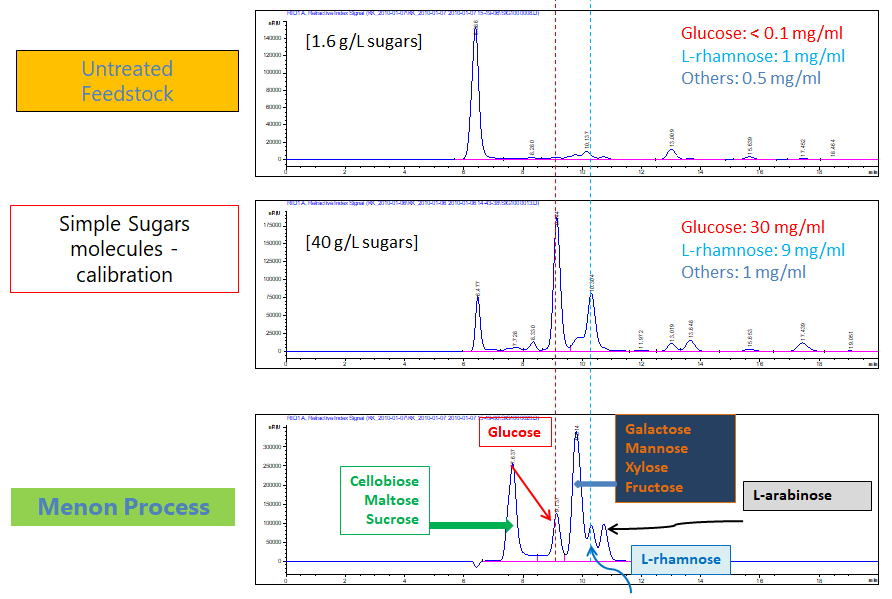

TheCeltherm™ process requires optimum levels of hydrocarbon sugars to get process going. Sugars from untreated feedstocks do not yield much. But after the Menon process of simultaneous saccharification and fermentation, higher levels of saccharified sugars are obtained

The Celtherm™ process starts with breakdown of cellulosic feedstocks into sugars. Over 1000 types of feedstocks are available in Menon library to utilize. During the process the optimal C:N ratio is established, followed by supercritical process, Oligomerization and optimization of mixing. The Menon team has the expertise to optimize sugar levels into the process from various feedstocks.

| Glucose | Xylose | Rhamnose | Other | |

| Corn stover | 103 | 50 | 17 | |

| Cane sugars | 74 | 39 | 27 | |

| Corn cob | 19 | 12 | 4 | |

| Wood | 2 | 92 | 11 | |

| Sorghum | 10 | 6 |