January 20, 2021 – As our global population continues to grow, food security and our ability to adequately feed everyone on the planet will be a central concern. While many have discussed the environmental impact of food production and its use of finite resources, something not as openly addressed is the supply chain of feed used in the raising of our protein sources.

Of the countless animal feed ingredients, one of the most prevalent is fishmeal due to its nutritional value. However, fishmeal is not sustainable in the long term given its relatively fixed availability and risk of over-fishing.

A sustainable functional ingredient

An alternative technology utilizes plant waste to create an amino acid profile, specifically valuable peptides that closely resemble fishmeal. Menon Renewable Products, Inc. (Menon), an ag-tech startup in San Diego, is one such company working to minimize reliance on fishmeal as a feed ingredient for aquaculture and livestock. Menon has developed a functional ingredient that can eliminate the need for fishmeal while achieving enhanced animal health and improved feed economics.

MrFeed®, the feed ingredient developed by Menon, is a disruptive technology that not only replaces fishmeal but has also proved to enhance animal growth and gut health. Through the inclusion of a spectrum of unique prebiotics, nucleotides and peptides, it enhances digestibility and promotes animal health while reducing the need for antibiotics and other disease remediation treatments.

The ingredient not only overcomes anti- nutritional factors in many animal feed products but also replaces various grains, related proteins, animal byproducts, fishmeal and other components.

The product was developed as the result of a project Dr. Suresh Menon was working on almost a decade ago when he was given a contract from the U.S. Department of Defense to hydrolyze agriculture inputs into sugars. His team found they were able to convert these inputs into proteins, lipids and other nutritional components. Following the completion of this project, and seeing the coming challenges in the animal feed industry, Dr. Menon identified a unique opportunity to provide a healthy and sustainable animal feed alternative.

This was the motivation behind the foundation of Menon Renewable Products in 2013.

With a history in biofuels and cellulosic waste processing, Dr. Menon has expertise in handling organic feedstocks to produce custom-tailored molecules and nutritional components. He was able to develop a patented process that converts hydrocarbon-based sugars from agriculture-based raw materials into a functional animal feed ingredient under the brand MrFeed®.

MrFeed® is a high-quality feed ingredient delivered without artificial preservatives that is rich in essential amino acids. Highly digestible and rich in protein, vitamins and minerals, the product has been developed specifically for use in aquaculture and livestock diets and provides enhanced animal health, superior growth and an improved FCR in order to meet the increasing worldwide demand for an abundant, sustainable, cost-competitive and renewable source of animal feed.

A scalable production process

The main differentiating factor between MrFeed® and other feed ingredients is the structure of the proteins from a molecular level. The size of the peptides can be controlled and make them smaller. As a result, the uptake of these small peptides in the bloodstream is easier, boosting the protein in the blood. This enhances the immune function of a given animal.

Through a proprietary and scalable process called CelTherm®, Menon converts hydrocarbon-based sugars from agriculture-based raw materials into an ingredient that utilizes hydrocarbons to create amino acids, fats, nucleotides, peptides and other key components of a functional animal feed ingredient.

The Celtherm® process requires optimum levels of hydrocarbon sugars to get the process going.

Sugars from untreated feedstocks do not yield much, but after the Menon process of simultaneous saccharification and fermentation, higher levels of saccharified sugars are obtained. The Celtherm® process starts with the breakdown of cellulosic feedstocks into sugars. Over 1,000 unique feedstocks are available in the Menon library to utilize. During the process, the optimal C:N ratio is established, followed by the supercritical processes of oligomerization and optimization of mixing.

The Menon team has the ability to optimize sugar levels from a wide variety of feedstocks to customize the ingredient for various animals. Thus MrFeed® Pro50 was developed as part of the MrFeed® line of functional ingredients specifically for shrimp. It is a shrimp feed ingredient with a minimum protein level of 50% and it contains a blend of amino acids, peptides and nucleotides that have been shown to not only promote growth but also enhance digestive health in animals.

A similar product is available for finfish.

MrFeed® is among the most sustainable options as an alternative for fishmeal. It is currently being produced at scale at prices that are competitive to fishmeal. Menon meets the growing demand for sustainable animal feed utilizing the company’s proprietary process that also reduces stress on the global environment by eliminating fishmeal and other non-sustainable animal feed ingredients. The process is highly scalable and the product lines can be produced from a variety of agricultural inputs, thus alleviating strain on natural resources.

Trial results

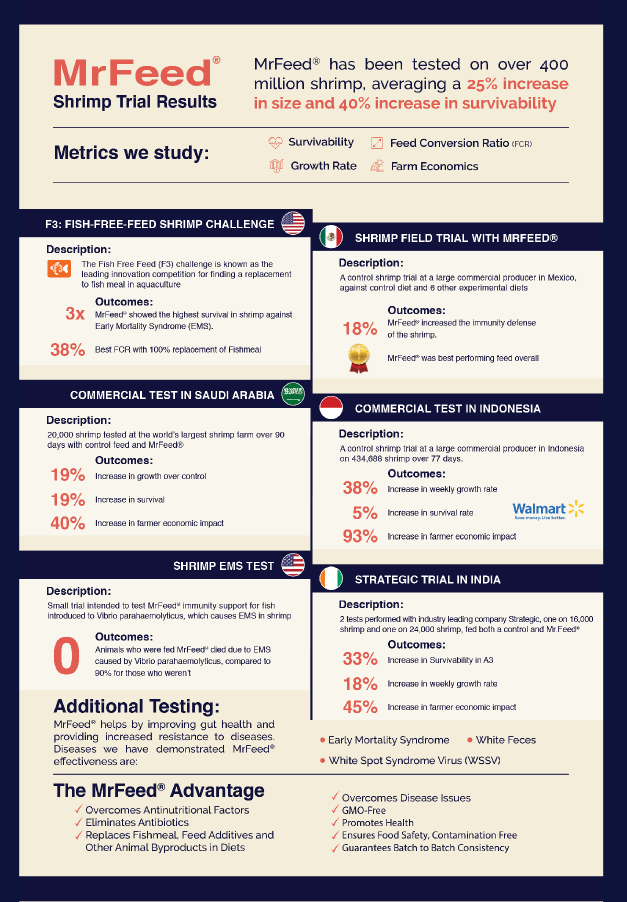

In addition to the company positioning the ingredient as an alternative to fishmeal, it has also conducted research suggesting that animals fed the product arehealt hier and grow faster than those on traditional diets. It has been proven in aquaculture, including shrimp and salmon and other finfish and has demonstrated superior performance when compared to traditional feeds in the areas of survivability, growth, disease remediation, Feed Conversion Ratio (FCR) and overall animal health.

In one trial, Menon leveraged the F3 (Future of Fish Feed) Feed Innovation Network (“F3 FIN”). Results from the trial demonstrated that shrimp feed formulations including MrFeed® at an 18% inclusion level, which fully replaced fishmeal, had significantly higher survival rates when exposed to Early Mortality Syndrome (EMS) when compared to the survivability of shrimp fed traditional diets containing fishmeal and fish oil. This proved that MrFeed® can replace fishmeal 100% while achieving significant increases in survivability and growth with overall yields in excess of 25% over traditional diets.

In another study conducted with Menon and National Aquaculture Group (Naqua), one of the world’s largest aquaculture operations based in Saudi Arabia, results indicated that shrimp fed diets containing 15% MrFeed® achieved higher survival, greater average body weight and improved feed conversion ratio (FCR) compared to all other test conditions. The study validated the premise that producers can significantly reduce the amount of fishmeal used in shrimp diets.

MrFeed® has been tested on more than 400 million shrimp in trials around the world, averaging a 25% increase in overall yield as enhanced immune system health drives faster growth and higher survival. The product has been tested extensively in commercial shrimp ponds worldwide in India, Indonesia, Malaysia, and many others. While additional testing is required, it presents a positive alternative to fishmeal with the potential to grow.